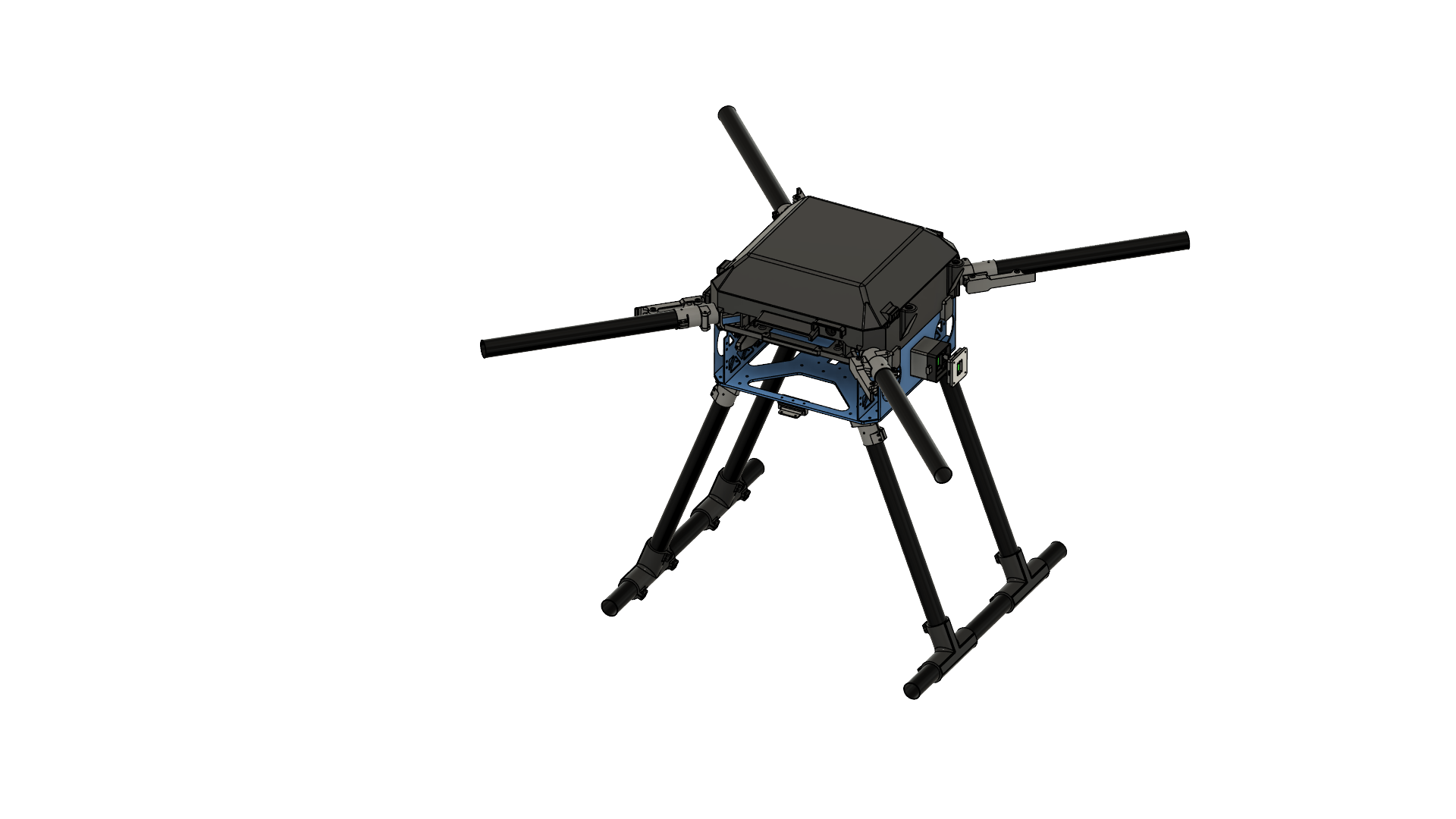

Project Quiver PT3 Structural Assembly Guide

BOM for the Assembly

Table 1. Structure parts

| Part ID | Part Name | CAD ID | Material | Sourcing | Quantity |

|---|---|---|---|---|---|

| 1 | Upper plate | 1101 | Aluminum | Laser Cut | 1 |

| 2 | Middle plate | 1102 | Aluminum | Laser Cut | 1 |

| 3 | Lower plate | 1103 | Aluminum | Laser Cut | 1 |

| 4 | Cockpit Support Beam CW Long | 1211 | Aluminum | Laser Cut | 1 |

| 5 | Cockpit Support Beam CCW Back | 1212 | Aluminum | Laser Cut | 1 |

| 6 | Cockpit Support Beam CCW Front | 1213 | Aluminum | Laser Cut | 1 |

| 7 | Battery Wall Left | 1221 | Aluminum | Laser Cut | 1 |

| 8 | Battery Wall Right | 1222 | Aluminum | Laser Cut | 1 |

| 9 | Foldable Motor Arm Connectors | 14X1 | Aluminum | Off-the-Shelf | 4 |

| 10 | Motor Arm Tubes | 14X2 | Carbon-Fiber | Cut-to-Length | 4 |

| 11 | Landing Gear Vertical Tubes | 1310 | Carbon-Fiber | Cut-to-Length | 4 |

| 12 | Landing Gear Horizontal Tubes | 1320 | Carbon-Fiber | Cut-to-Length | 2 |

| 13 | Landing Gear Main Adapters | 1330 | Aluminum | Off-the-Shelf | 4 |

| 14 | Enclosure Hinge | 2430 | Zinc | Off-the-Shelf | 2 |

| 15 | Landing Gear Tube Joints | 1340 | PETG-CF | 3D Print | 4 |

| 16 | Battery sliders | 2200 | PETG-CF | 3D Print | 2 |

| 17 | BC PCB Cover | 2313 | PETG-CF | 3D Print | 1 |

| 18 | Altitude Sensor Mount | 2330 | PETG-CF | 3D Print | 1 |

| 19 | Enclosure Anchors | 2420 | PETG-CF | 3D Print | 4 |

| 20 | Camera Mount | 2320 | PETG-CF | 3D Print | 1 |

| 21 | Attachment Interface Spacer Left | 2121 | PETG-CF | 3D Print | 1 |

| 22 | Attachment Interface Spacer Right | 2111 | PETG-CF | 3D Print | 1 |

| 23 | Attachment Interface Spacer Bottom | 2131 | PETG-CF | 3D Print | 1 |

| 24 | GNSS Mount Base | 2341 | PETG | 3D Print | 1 |

| 25 | GNSS Mount Clamp | 2342 | PETG | 3D Print | 1 |

| 26 | Main PCB Mount | 2311 | PETG | 3D Print | 1 |

| 27 | Main Enclosure | 2411 | PETG | 3D Print | 1 |

| 28 | Enclosure Top Cap | 2412 | PETG | 3D Print | 1 |

| 29 | Enclosure Cap Clips | 2440 | PETG | 3D Print | 4 |

| 30 | BC PCB Mount | 2312 | PETG | 3D Print | 1 |

| 31 | Attachment Interfaces | 2122 | Aluminum | Off-the-Shelf | 3 |

Table 2. Fasteners

| Fastener ID | Fastener Description | Quantity | McMaster-Carr Reference |

|---|---|---|---|

| Rivet 1 | 4mm Diameter for 2.5 mm - 4.5 mm thickness | 36 | 97525A251 |

| Rivet 2 | 4mm Diameter for 4.5 mm - 6.4 mm thickness | 10 | 97525A226 |

| Screw 1 | Socket Head Screw M3x10 | 48 | 91290A115 |

| Screw 2 | Flanged Button Head Screw M4x10 | 16 | 97654A373 |

| Screw 3 | Socket Head Screw M3x16 | 24 | 91292A115 |

| Screw 4 | Socket Head Screw M3x12 | 12 | 91290A117 |

| Screw 5 | Socket Head Screw M3x8 | 23 | 91290A113 |

| Screw 6 | Socket Head Screw M3x40 | 16 | 91290A136 |

| Screw 7 | Hex Drive Flat Head Screw M3x8 | 8 | 92125A128 |

| Screw 8 | Hex Drive Flat Head Screw M3x10 | 4 | 91294A130 |

| Screw 9 | Socket Head Screw M4x8 | 8 | 91290A140 |

| Screw 10 | Hex Drive Flat Head Screw M3x25 | 3 | 91294A138 |

| Insert 1 | M3 Threaded Inserts | 50 | 97163A161 |

| Insert 2 | M4 Threaded Inserts | 8 | 97163A153 |

| Washer 1 | General Purpose Washer 3.2 mm ID, 6 mm OD | 158 | 98689A112 |

| Washer 2 | General Purpose Washer 4.3 mm ID, 9 mm OD | 8 | 93475A230 |

| Nut 1 | Nylon-Insert Locknut M3 | 39 | 90576A811 |

Preparation

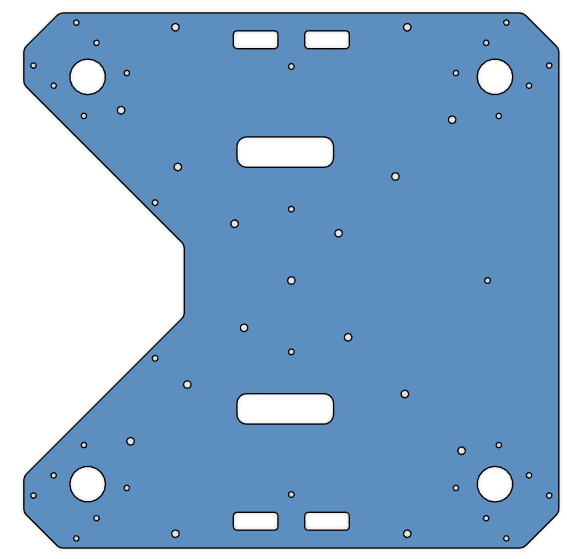

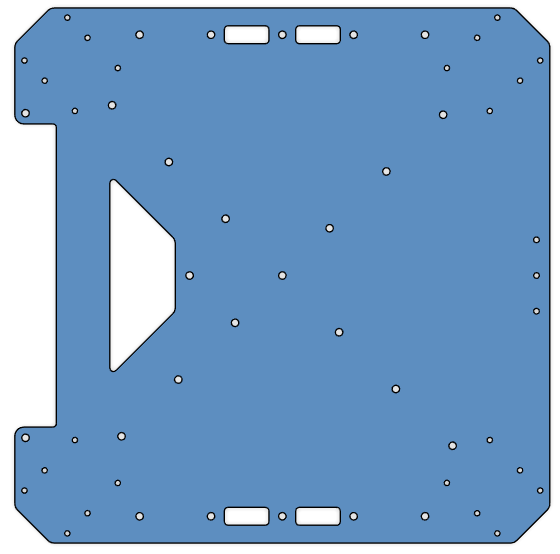

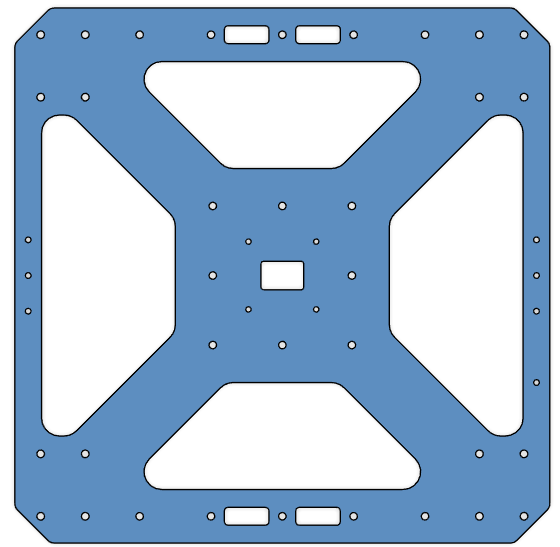

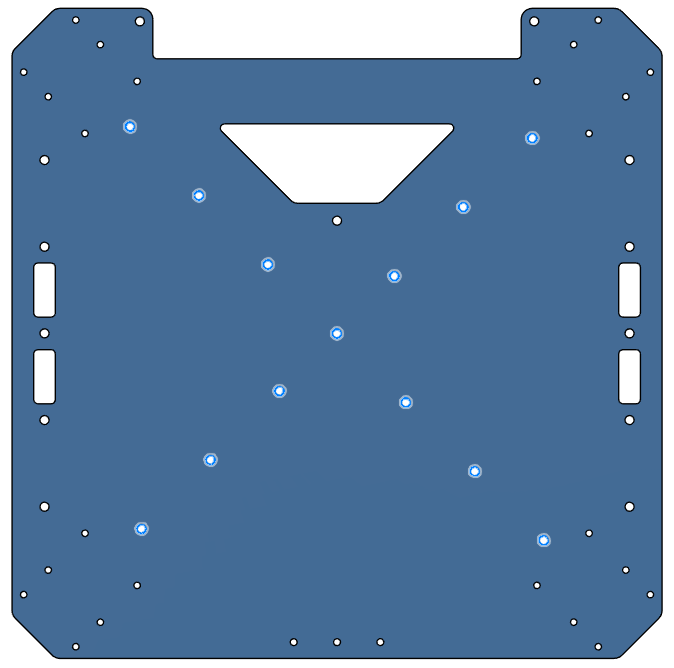

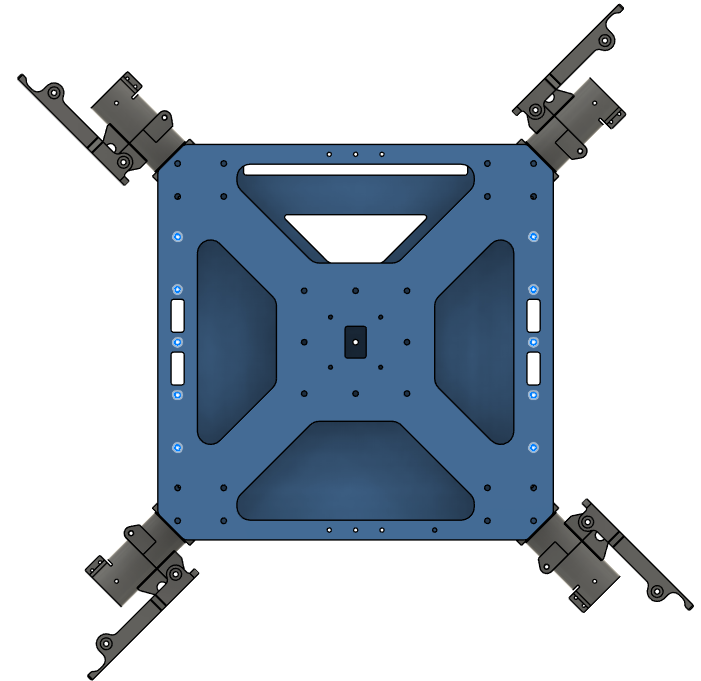

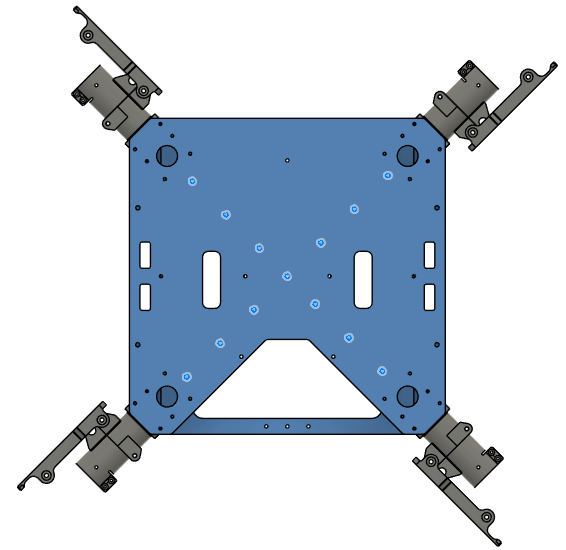

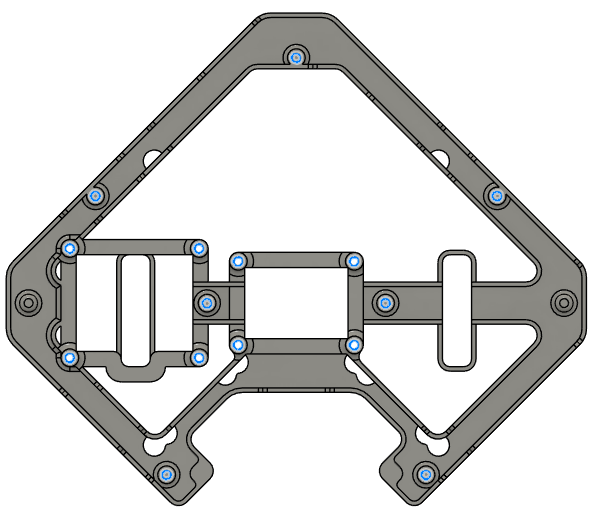

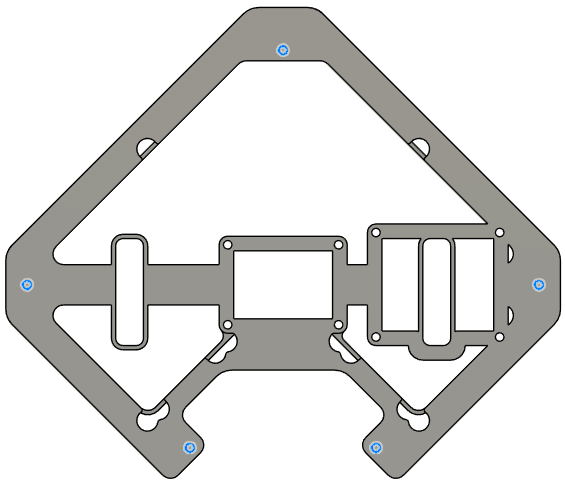

Parts 1-3

- All three are aluminum 6 series sheets, laser cut, sanded.

- Bounding box dimension is 300x300x2 mm for each.

| Part 1 (Upper Plate) | Part 2 (Mid Plate) | Part 3 (Lower Plate) | |

|---|---|---|---|

| Thickness | 2 mm | 2 mm | 4 mm |

| Image |  |  |  |

| CAD File | Part 1 | Part 2 | Part 3 |

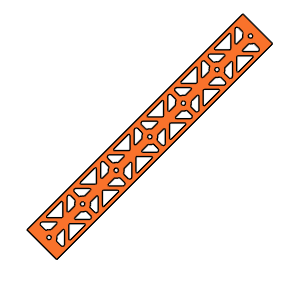

Parts 4-6

- All three are aluminum 6 series, 40x40x2 mm square tubes, laser cut, sanded.

- Part 5 and Part 6 are identical, order 2 parts for the same geometry.

| Part 4 (Cockpit Support Beam CW Long) | Part 5 & 6 (Cockpit Support Beam CCW Back & Front) | |

|---|---|---|

| Length | 289.2 mm | 124.2 mm |

| Image |  | |

| CAD File | Part 4 | Part 5 & 6 |

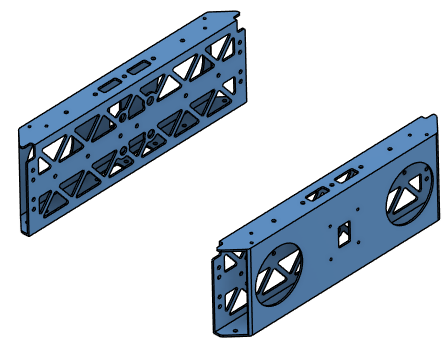

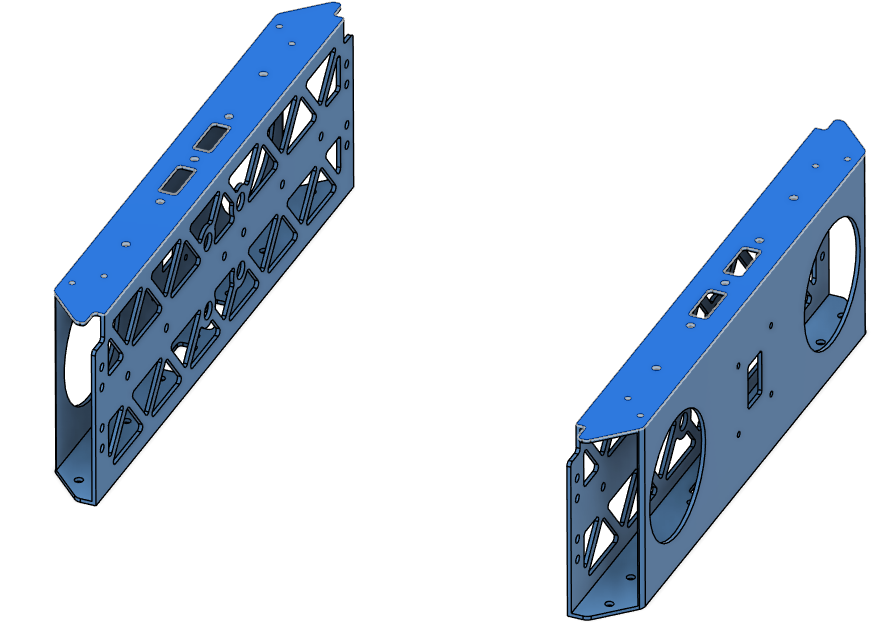

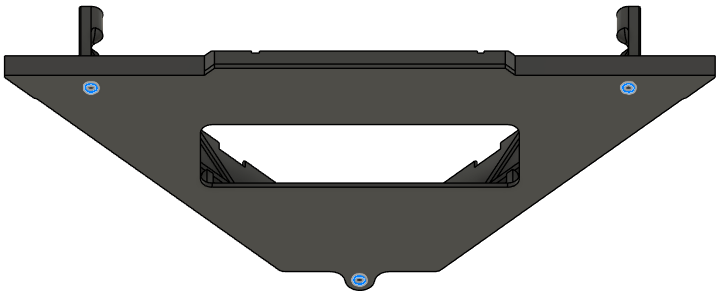

Parts 7-8

- Both are aluminum 6 series, 1000x30x2 mm rectangular tubes, laser cut, sanded.

- Length is 300 mm for each.

- Parts are identical, order 2 parts of the same geometry.

| Part 7 & 8 (Battery Wall Left & Right) | |

|---|---|

| Image |  |

| CAD File | Part 7 & 8 |

Part 9

- Off-the-shelf component.

- 30 mm option.

- 4 parts in total.

- Product Link: Link

Parts 10-12

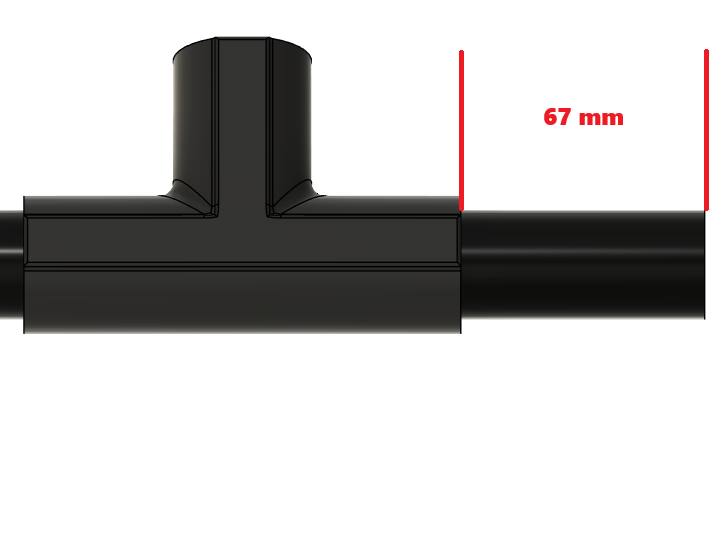

- 30x2 mm circular carbon-fiber tubes with different lengths.

- Reference link: Link

- Order 5 x 1000 mm or 10 x 500 mm

| Part 10 (Motor Arms) | Part 11 (Landing Leg Vertical Tubes) | Part 12 (Landing Leg Horizontal Tubes) | |

|---|---|---|---|

| Length | 360 mm | 400 mm | 500 mm |

| Quantity | 4 | 4 | 2 |

Part 13

- Off-the-shelf component.

- 30 mm option.

- 4 parts in total.

- Product Link: Link

Part 14

- Off-the-shelf component.

- Part Number: GN 237-ZD-30-30-A-SW

- 2 parts in total.

- Product Link: Link

Parts 15-23

- All 3D printed parts.

- They have structural roles on the airframe. Use PETG-CF filament.

- STL link: Parts 15-23

| Part | Quantity |

|---|---|

| Part 15 | 4 |

| Part 16 | 2 |

| Part 17 | 1 |

| Part 18 | 1 |

| Part 19 | 4 |

| Part 20 | 1 |

| Part 21 | 1 |

| Part 22 | 1 |

| Part 23 | 1 |

Parts 24-30

- All 3D printed parts.

- The parts should not interfere with GNSS signals. Use PETG filament.

- DO NOT use any filament containing carbon fiber.

- STL link: Parts 24-30

| Part | Quantity |

|---|---|

| Part 24 | 1 |

| Part 25 | 1 |

| Part 26 | 1 |

| Part 27 | 1 |

| Part 28 | 1 |

| Part 29 | 4 |

| Part 30 | 1 |

Part 31

- Off-the-shelf component.

- Order without PCB.

- 3 parts in total.

- Product Link: Link

Tool List

- You need the following tools:

- Allen key set

- Wrench set

- Cordless screwdriver or drill press

- Riveting tool

- Loctite Threadlocker Blue 242

- Adhesive: Loctite Superflex Silicon Sealant Model 593, 6.4 fl. oz.

- A cleaning agent to prepare the surfaces before adhesive

Assembly Steps

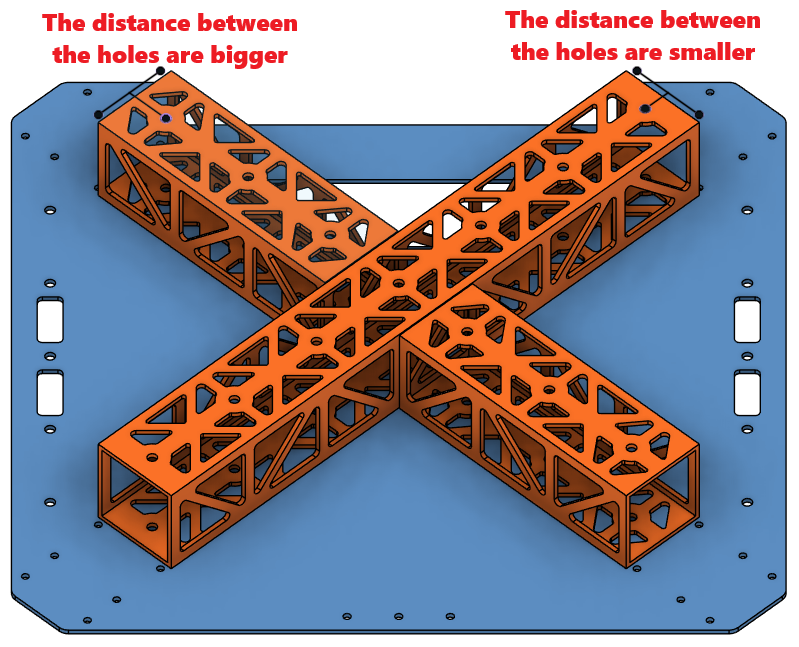

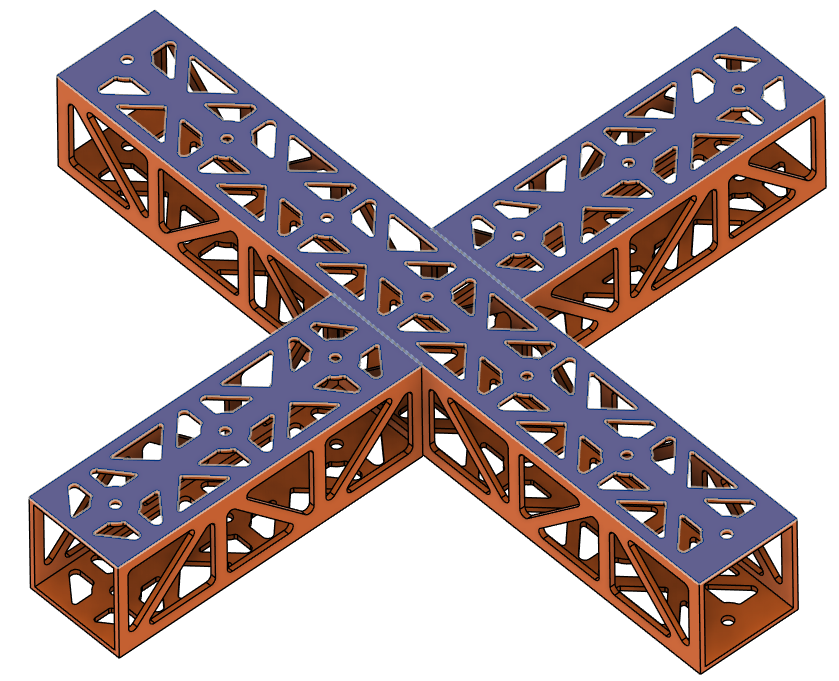

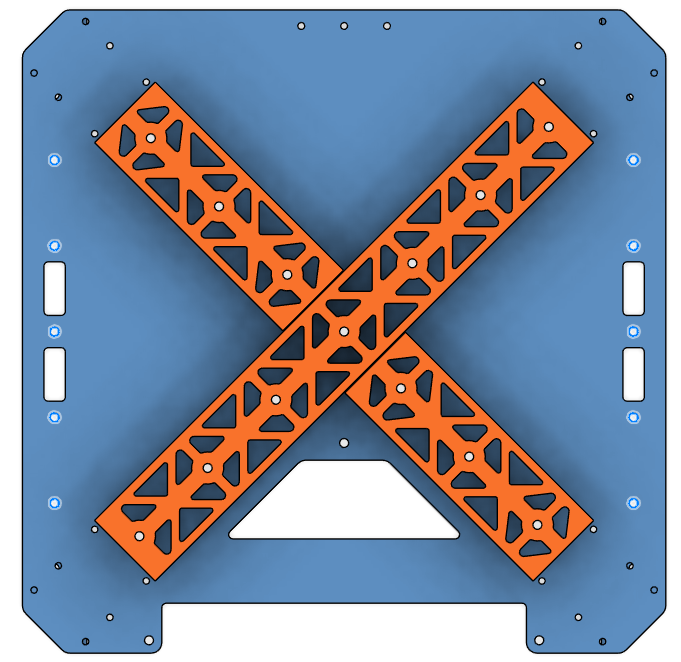

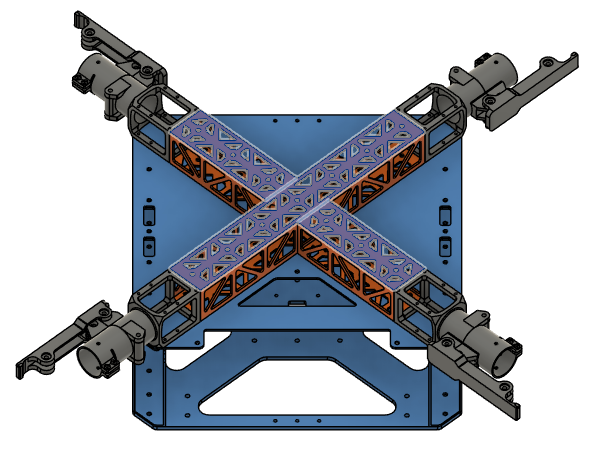

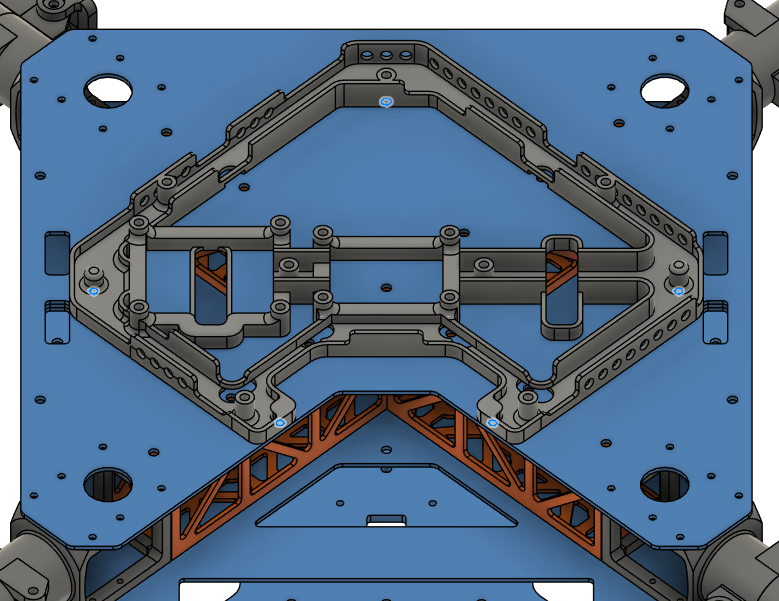

Step 1. Assemble the Cockpit Support Beams on Mid Plate

-

Parts needed:

- Part 2 (Mid Plate)

- Parts 4, 5, 6 (Cockpit Support Beams)

- Rivet 1 x13

-

Apply adhesive on the cockpit support beams around the holes on the contact side.

-

Place the cockpit support beams on the mid plate as shown to the picture.

-

Rivet the cockpit support beams from the mid plate on the holes shown in the picture.

- Make sure you rivet before the adhesive dries.

| Orientation | Adhesive Area | Rivet Holes |

|---|---|---|

|  |  |

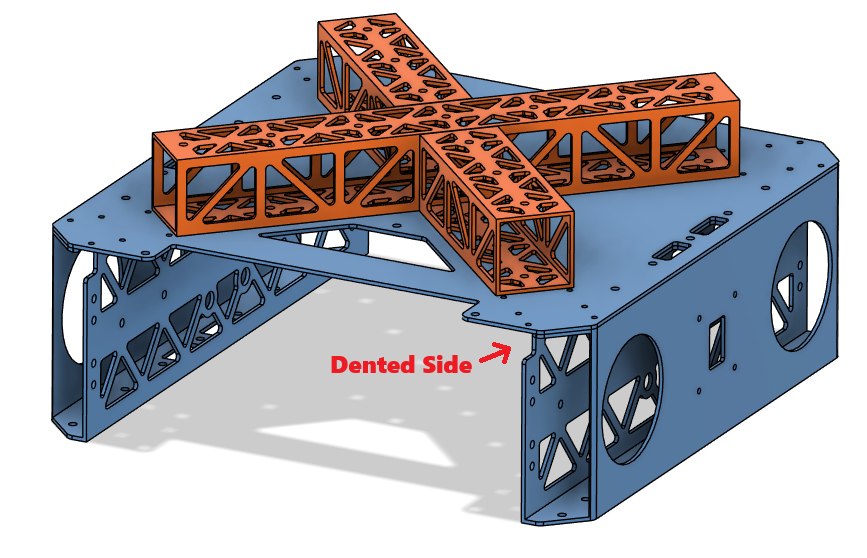

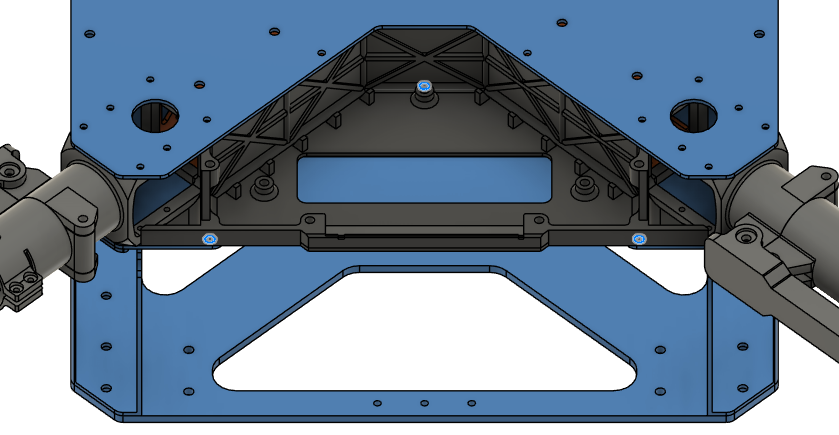

Step 2. Install the Battery Walls

- Parts needed:

- Step 1 chassis

- Parts 7, 8 (Battery Walls)

- Rivet 1 x10

- Apply adhesive on the battery walls around the holes on the contact side.

- Place the battery walls on the sides of the chassis as shown in the picture.

- Make sure the dented side stays on the chassis side.

- Rivet the battery walls from the mid plate on the holes shown in the picture.

- Make sure you rivet before the adhesive dries.

| Orientation | Adhesive Area | Rivet Holes |

|---|---|---|

|  |  |

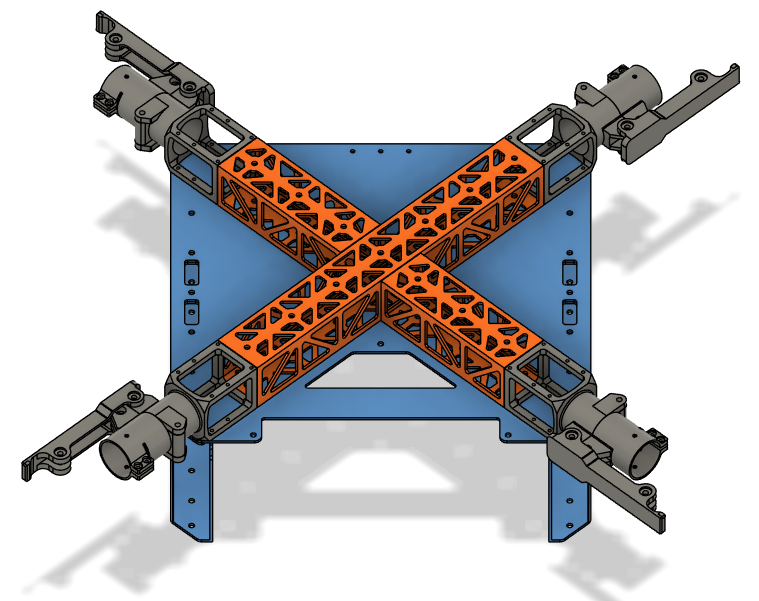

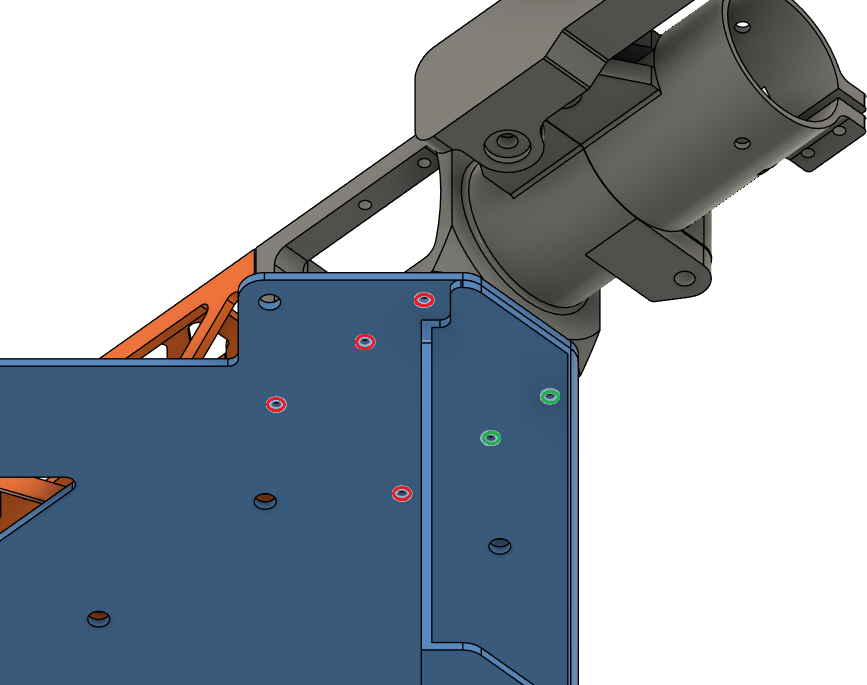

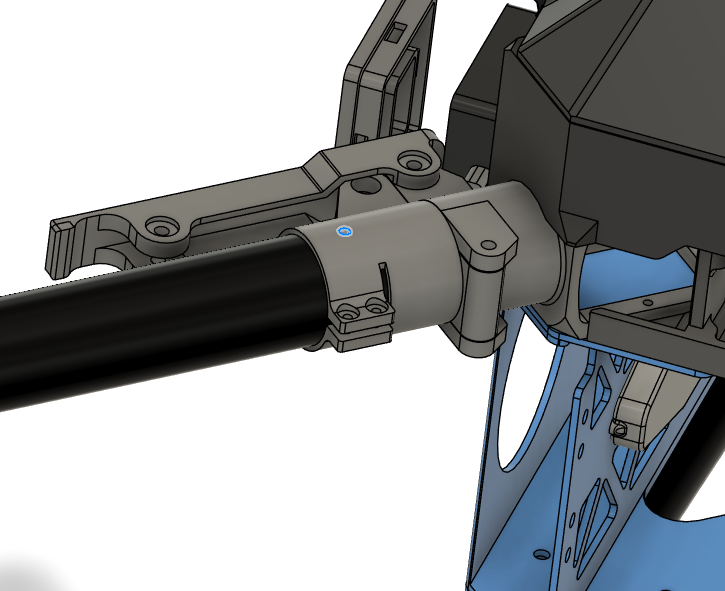

Step 3. Install the Motor Arm Connectors

- Parts needed:

- Step 2 chassis

- Part 9 x4 (Foldable Motor Arm Connectors)

- Screw 1 x16

- Screw 4 x8

- Washer 1 x24

- Place the motor arm connectors on the chassis as shown in the picture.

- Secure the motor arm connectors on the chassis.

- Use Screw 1 for red holes and Screw 4 for green holes.

- Use Loctite Threadlocker.

- Use Washer 1.

- Use cordless screwdriver where possible, or else an allen key.

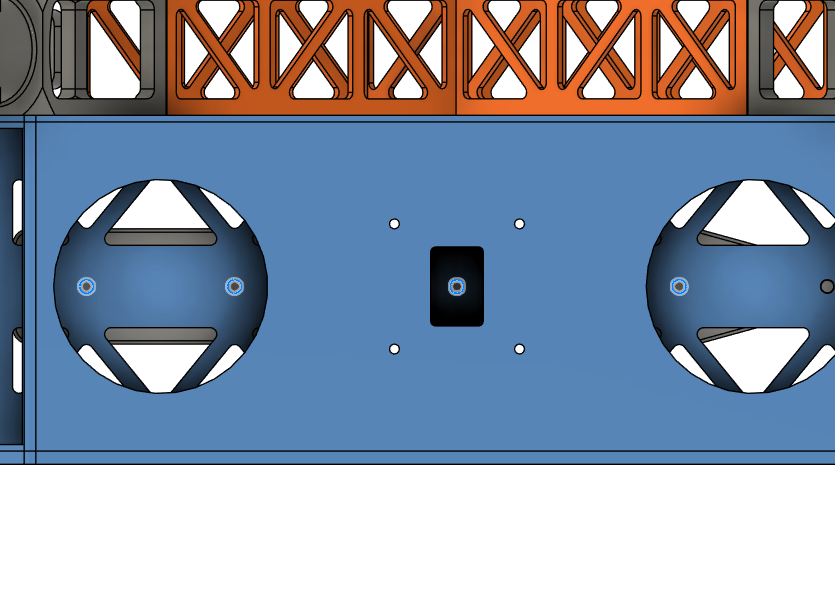

| Orientation | Screw Holes |

|---|---|

|  |

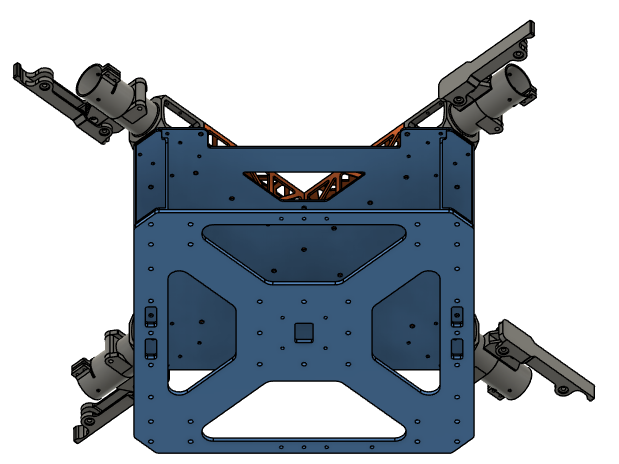

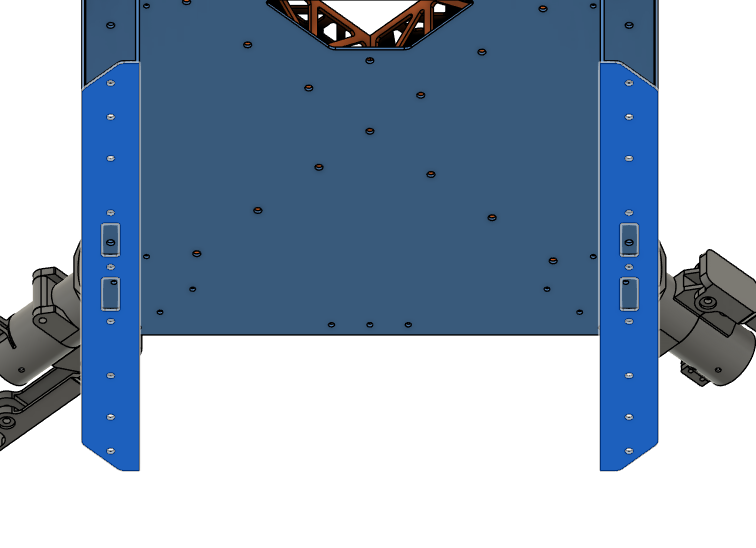

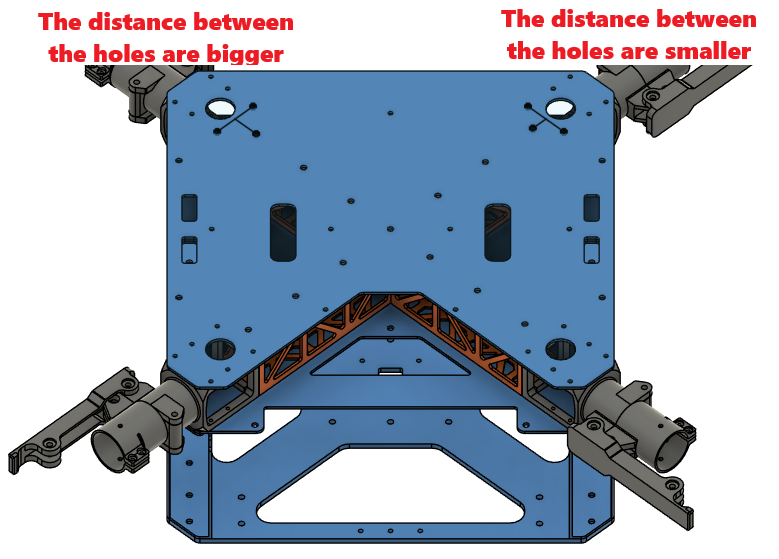

Step 4. Install the Lower Plate

- Parts needed:

- Step 3 chassis

- Part 3 (Lower Plate)

- Rivet 2 x10

- Place the lower plate on the chassis as shown to the picture.

- Apply adhesive on the battery walls around the holes on the contact side.

- Rivet the lower plate to the chassis on the holes shown in the picture.

- Make sure you rivet before the adhesive dries.

| Orientation | Adhesive Area | Rivet Holes |

|---|---|---|

|  |  |

Step 5. Install the Upper Plate

-

Parts needed:

- Step 4 chassis

- Rivet 1 x13

- Screw 1 x24

- Washer 1 x24

-

Place the upper plate over the chassis as shown to the picture.

-

Apply adhesive on the cockpit support beams around the holes on the contact side.

-

Rivet the cockpit support beams from the upper plate on the holes shown in the picture.

- Make sure you rivet before the adhesive dries.

-

Screw the motor arm connecters from the upper plate with Screw 1.

- Use Washer 1.

- Use Loctite Threadlocker.

| Orientation | Adhesive Area | Rivet Holes |

|---|---|---|

|  |  |

Step 6. Install the Battery Connector PCB Mount

-

Parts needed:

- Step 5 chassis

- Part 26 (Main PCB Mount)

- Insert 1 x20

- Screw 5 x20

- Washer 1 x20

-

Place Insert 1 to the holes shown in the picture, on the top and bottom sides of the main PCB mount.

- Use a soldering iron to place them inside the plastic.

| Top | Bottom |

|---|---|

|  |

- Place the main PCB mount over the upper plate.

- Secure it with 5x Screw 5 in total from below the upper plate on the holes below.

- Use Washer 1 for the holes.

Step 7. Install the Main PCB Mount

-

Parts needed:

- Step 6 chassis

- Part 30 (BC PCB Mount)

- Insert 1 x10

- Screw 5 x3

- Washer 1 x3

-

Place Insert 1 to the holes shown in the picture, on the top and bottom sides of the BC PCB mount.

- Use a soldering iron to place them inside the plastic.

| Top | Bottom |

|---|---|

|  |

- Place the Battery Connector PCB mount over the mid plate.

- Secure it with 3x Screw 5 in total from below the mid plate on the holes below.

- Use Washer 1 for the holes.

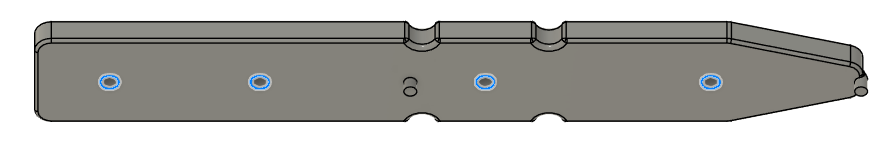

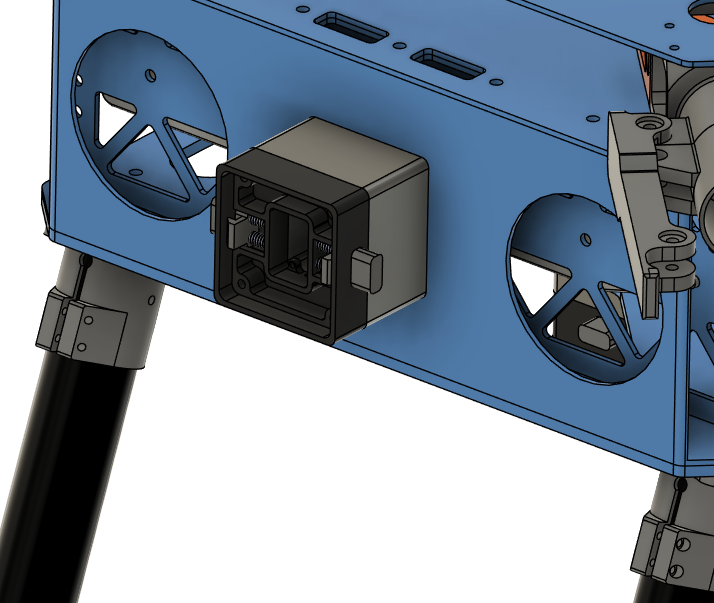

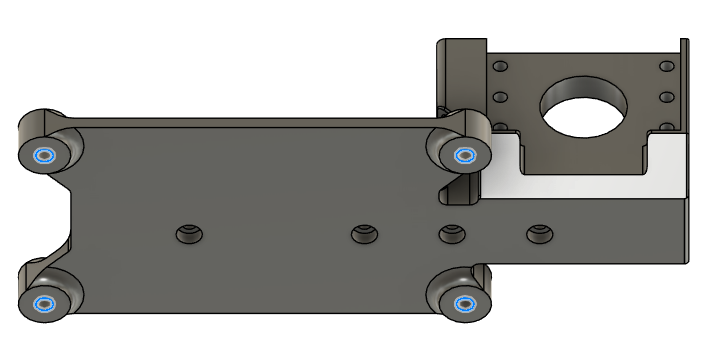

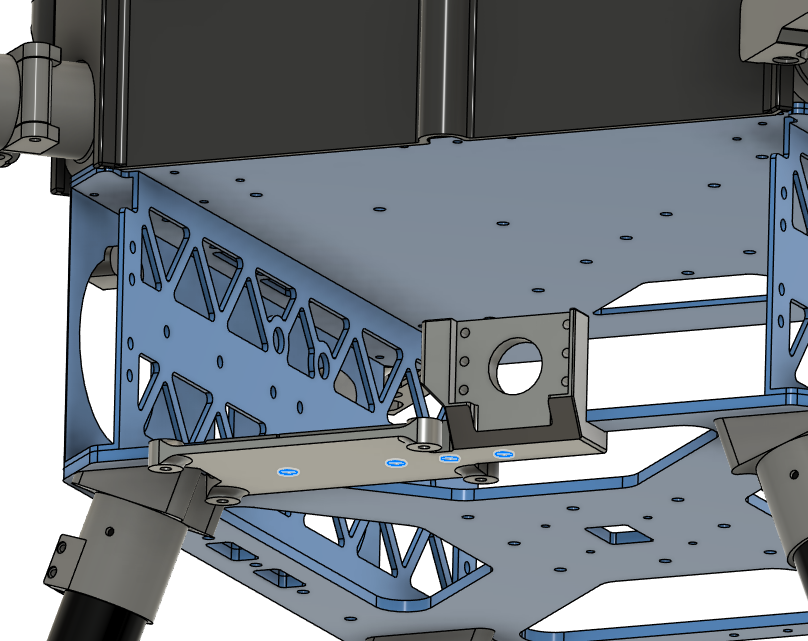

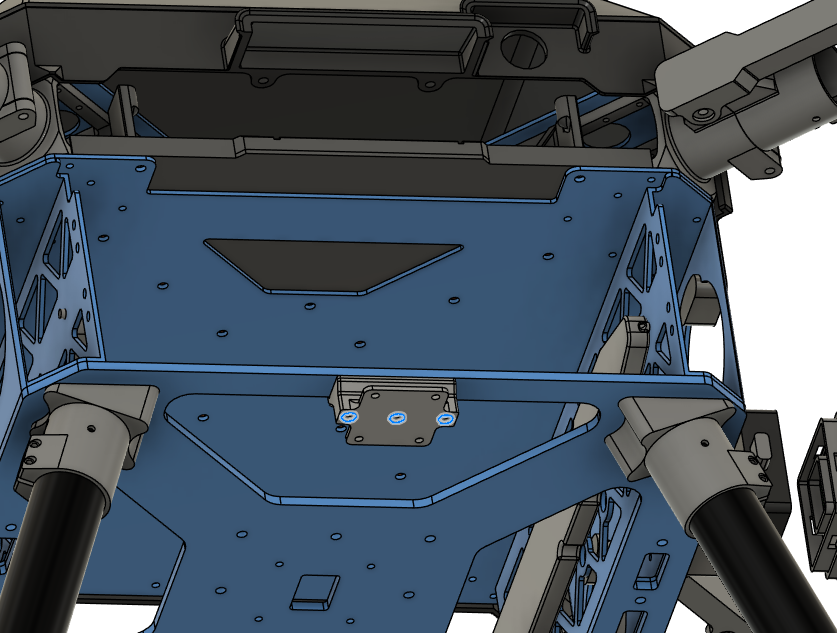

Step 8. Install the Battery Sliders

-

Parts needed:

- Step 7 chassis

- Part 16 (Battery Sliders)

- Insert 2 x8

- Screw 9 x8

- Washer 2 x8

-

Place Insert 2 to the holes shown in the picture on both of the battery slides.

- Use a soldering iron to place them inside the plastic.

- Place the battery sliders inside the battery compartment.

- Be careful about the orientation of the angled end, they should point where the cutouts on the plates are.

- Secure it with 8x Screw 9 in total from the sides of the frame.

- Use Washer 2 with the screws.

| Orientation | Installation Holes |

|---|---|

|  |

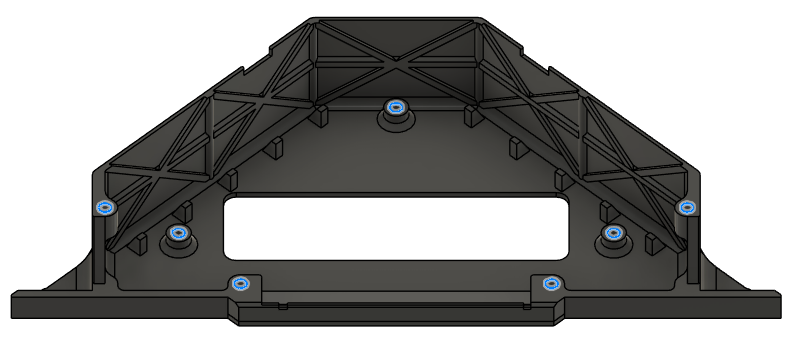

Step 9. Install the Landing Gear

- Parts needed:

- Step 8 chassis

- Part 11, 12 (Landing Gear Horizontal & Vertical Tubes)

- Part 13 (Landing Gear Main Adapters)

- Part 15 (Landing Gear Tube Joints)

- Screw 2 x16

- Screw 3 x24

- Washer 1 x56

- Nut 1 x28

- Screw 6 x4

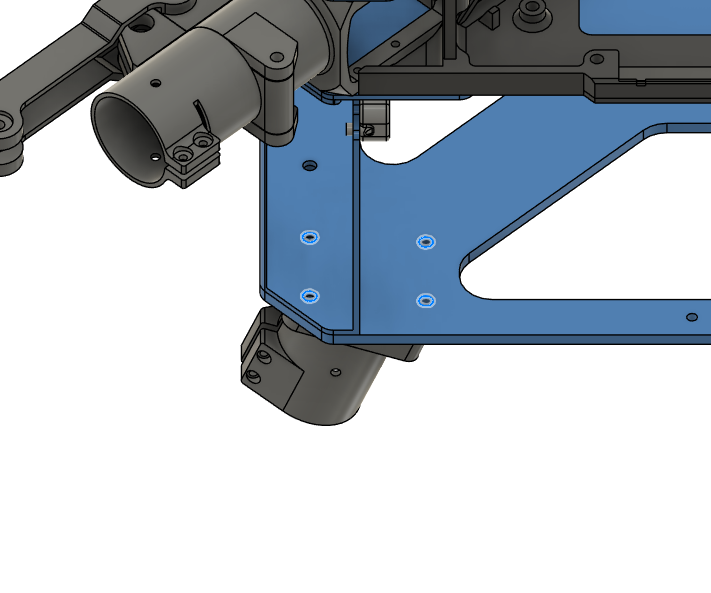

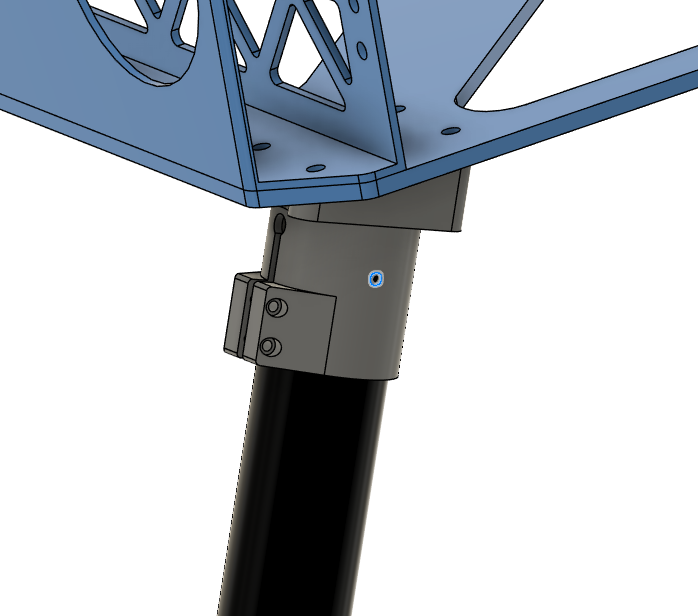

- Place the landing gear main adapters below the chassis, as shown in the picture.

- The adapters are facing outside to the left and right of the structure.

- Screw the adapters with 16x Screw 2 to the chassis.

- Use Loctite Threadlocker to secure the screws.

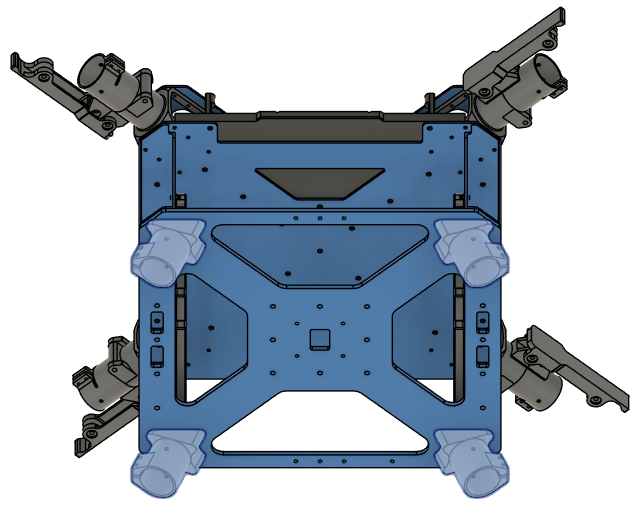

| Orientation | Installation Holes |

|---|---|

|  |

- Insert the vertical landing gear tubes inside landing gear main adapters.

- Make sure the tubes are inserted all the way.

- Tighten the clamps with the screws provided in the landing gear main adapter package.

- Use Loctite Threadlocker to secure the screws.

-

Make sure the chassis stands level on the ground.

- If not, measure and equalize the tube lengths.

-

Drill the tubes with 3 mm drill bit on the marked holes.

- Use Screw 6.

- Use Washer 1 on each side.

- Use Nut 1.

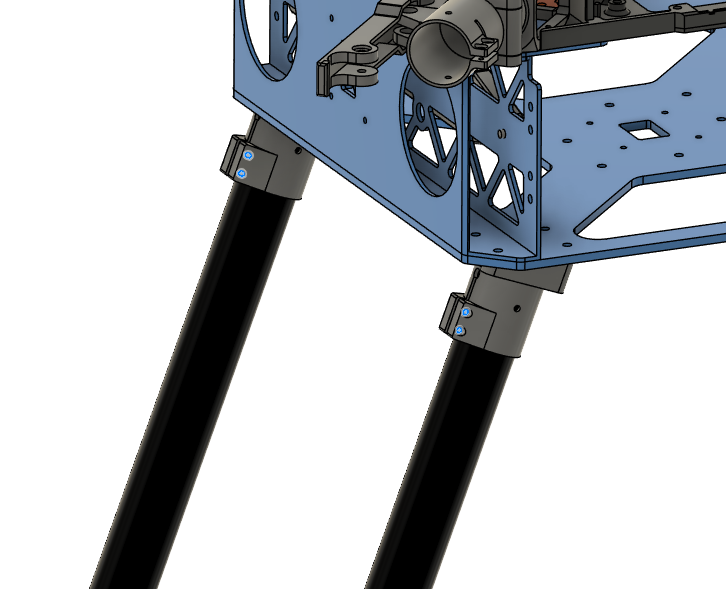

- Assemble landing gear tube joints and the horizontal tubes as shown in the picture.

- Insert the vertical tubes inside the holes before tightening the screws.

- Use Screw 3.

- Use Washer 1 on each side.

- Use Nut 1.

| Positioning | Installation Holes |

|---|---|

|  |

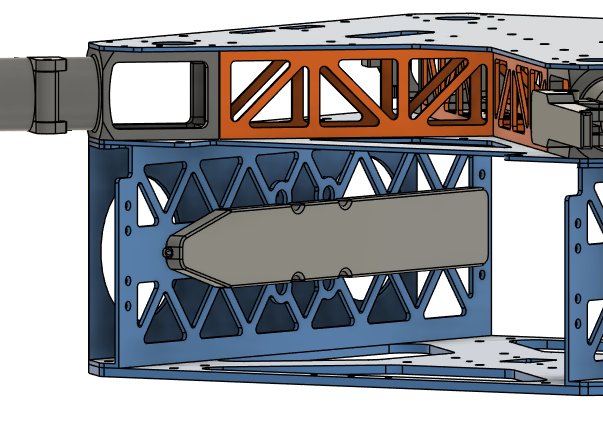

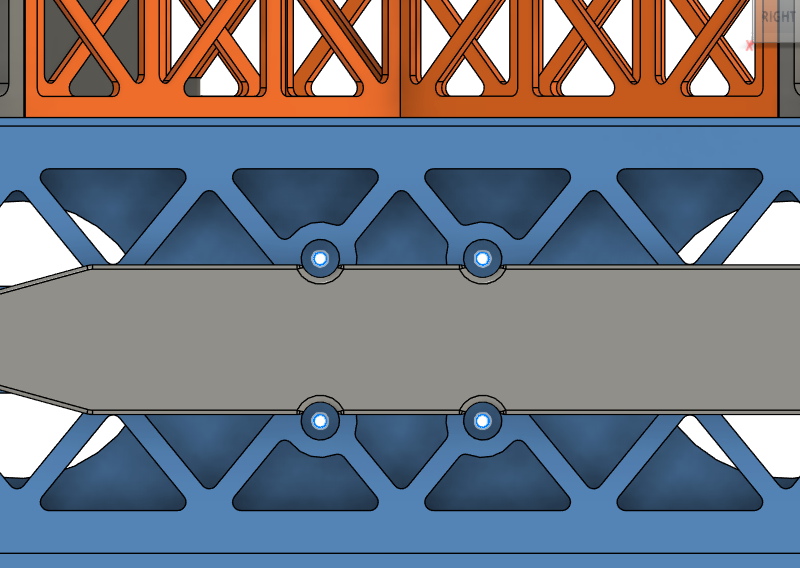

Step 10. Install Side Attachment Interfaces

-

Parts needed:

- Step 9 chassis

- Part 21, 22 (Side Attachment Interface Spacers)

- Part 31 (Attachment Interfaces)

- Screw 6 x8

- Washer 1 x8

-

Place and secure side attachment interfaces and the spacers as shown in the pictures.

- Make sure the rectangular holes are aligned with the holes on the battery walls.

- Use the screwdriver holes inside the battery compartment to place the screws and the screwdriver.

- Use Screw 6.

- Use Washer 1.

- Use Loctite Threadlocker.

| Positioning | Installation Holes |

|---|---|

|  |

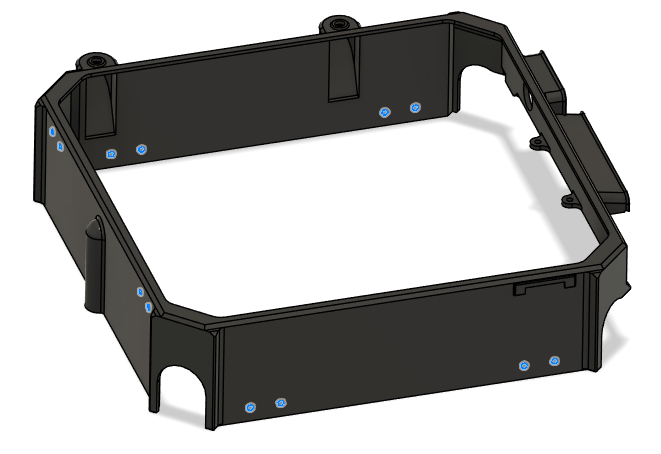

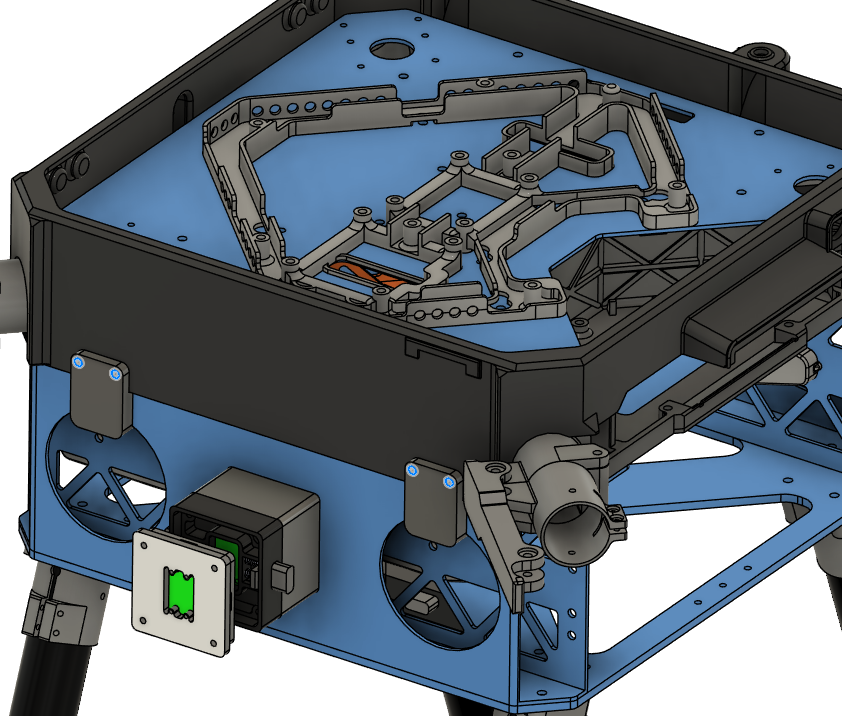

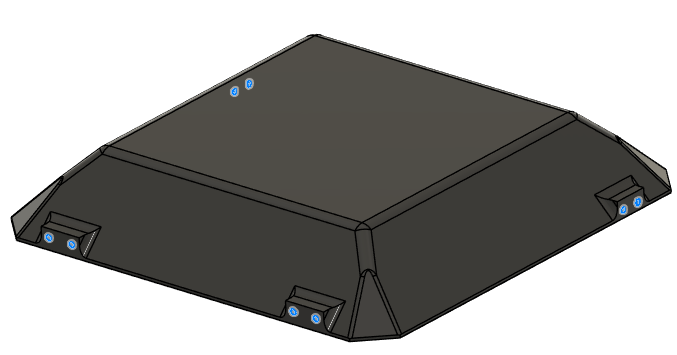

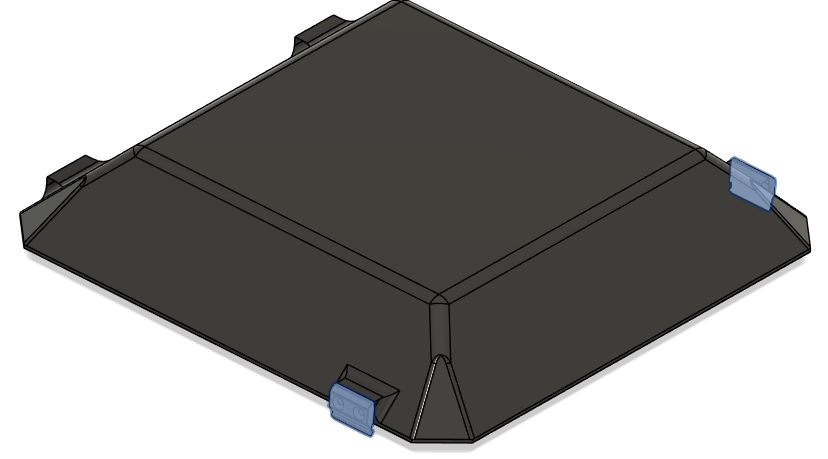

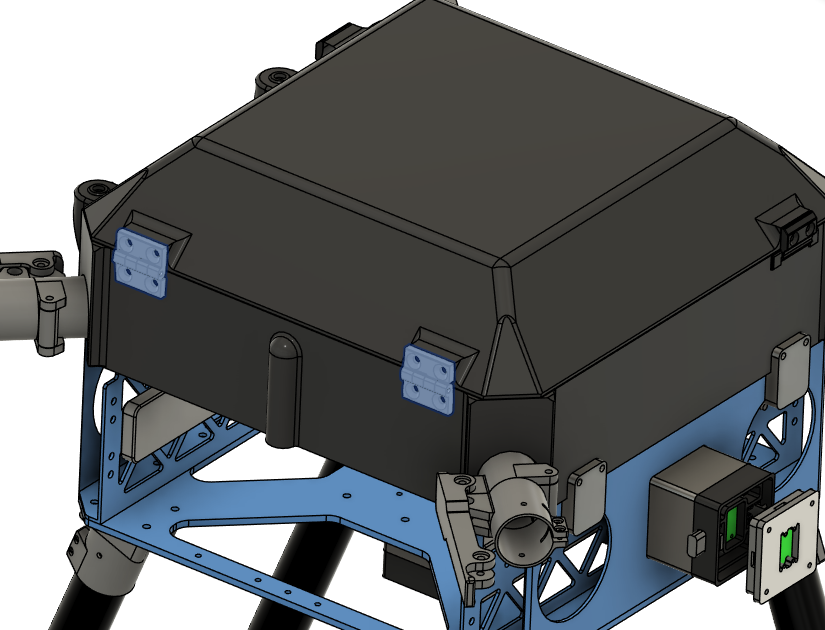

Step 11. Install Cockpit Enclosure

-

Parts needed:

- Step 10 chassis

- Part 27 (Main Enclosure)

- Part 28 (Enclosure Top Cap)

- Part 14 (Enclosure Hinge)

- Part 29 (Enclosure Cap Clips)

- Part 19 (Enclosure Anchors)

- Screw 1 x8

- Screw 7 x8

- Screw 8 x4

- Washer 1 x8

- Insert 1 x20

-

Place Insert 1 to the holes shown in the picture from outside on the main enclosure.

- Use a soldering iron to place them inside the plastic.

- Place the enclosure anchors and the main enclosure over the chassis.

- The anchors will fit on the circular cutouts on the battery walls.

- Mind the direction of the main enclosure.

- Screw the anchors to the main enclosure with Screw 1.

- Use Washer 1.

- DO NOT use Loctite Threadlocker.

- Place Insert 1 to the holes shown in the picture from outside on the top cap.

- Use a soldering iron to place them inside the plastic.

- Place the enclosure clips on the top cap as shown in the picture.

- Screw the anchors to the main enclosure with Screw 8.

- DO NOT use Loctite Threadlocker.

- Screw the anchors to the main enclosure with Screw 8.

- Place the top cap over the chassis.

- Secure the enclosure hinges on the top cap and the main enclosure.

- Use Screw 7.

- DO NOT use Loctite Threadlocker.

Step 12. Install Altitude Sensor Mount

-

Parts needed:

- Step 11 chassis

- Part 18 (Altitude Sensor Mount)

- Screw 4 x4

- Washer 1 x4

- Nut 1 x4

-

Place Insert 1 to the holes shown in the picture.

- Use a soldering iron to place them inside the plastic.

- Secure the altitude sensor mount on the lower plate.

- Screw head stays inside the mount.

- Use Screw 3.

- Use Washer 1 on the nut side.

- Use Nut 1.

- DO NOT use Loctite Threadlocker.

Step 13. Install Camera Mount

-

Parts needed:

- Step 12 chassis

- Part 20 (Camera Mount)

- Screw 10 x3

- Washer 1 x3

- Nut 1 x3

-

Secure the altitude sensor mount on the lower plate.

- Screw head stays under the mount.

- Use Screw 10.

- Use Washer 1 on the nut side.

- Use Nut 1.

- DO NOT use Loctite Threadlocker.

Step 14. Install Motor Arm Tubes

-

Parts needed:

- Step 13 chassis

- Part 10 (Motor Arm Tubes)

- Screw 6 x4

- Washer 1 x8

- Nut 1 x4

-

Insert the motor arm tubes inside the motor arm connectors.

- Make sure the tubes are inserted all the way.

- Tighten the clamps with the screws provided in the motor arm connector package.

- Use Loctite Threadlocker to secure the screws.

- Drill the tubes with 3 mm drill bit on the marked holes.

- Use Screw 6.

- Use Washer 1 on each side.

- Use Nut 1.

- The structural assembly is completed.

- Keep GNSS mount, GNSS mount clamp and BC PCB cover parts for the general assembly.